A dishing tool is used to check that the rim is centered between the hub ends during wheel building or truing. In the mid-1980’s, being a poor high-school kid, I built a wheel dishing tool out of a 2×4 with a bite cut out of the center, and a screw assembly from a cheap stamped c-clamp. Over the years the tool took a beating from multiple moves and not enough care in storing it.

I have the cheapest truing stand known to man, which does not automatically center the feelers so if I’m not careful, I can walk the rim out of dish while truing.

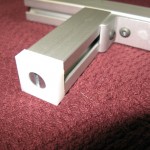

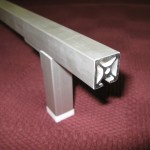

I was going to buy a dishing tool, but the ones available today aren’t too impressive and cost more than one I could build out of 80-20 aluminum extrusions. I used my little machine tools and put one together for about $30. The main components are 10 series single slot 80-20; the main beam is 30″ long, and the arms are 3 inches long. The center feeler is a piece of 1/4-20 all thread with some hardware store knobs on the outside, and a simple turned feeler on the inside. The pictures are below:

|

|